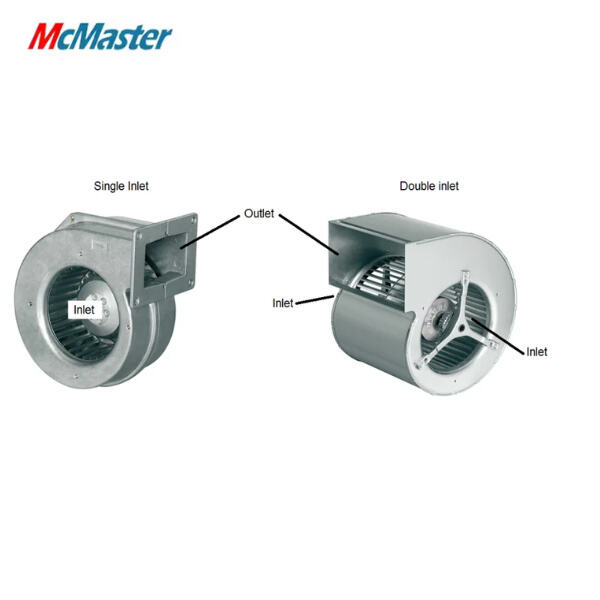

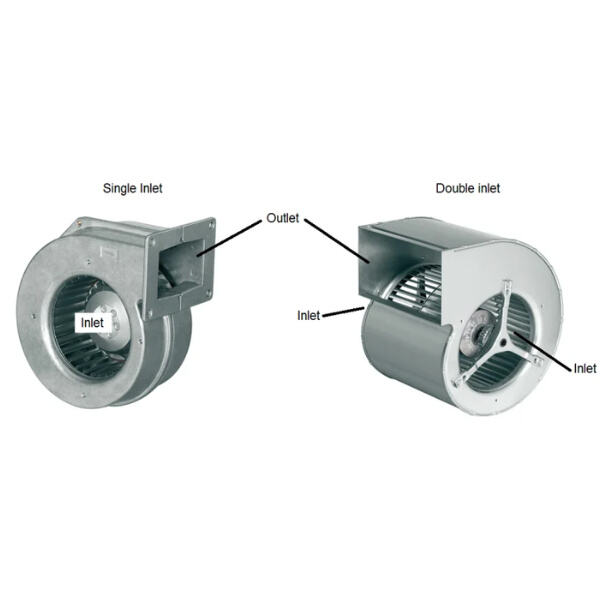

هل سبق لك أن تساءلت عن تدفق الهواء في المباني الكبيرة مثل المدارس والمعامل وحتى المستشفيات؟ إنه أمر في غاية الاهتمام! ماكماستر إلكتريك ب محرك تيار مستمر بدون فرشاة هو أداة مهمة تُجبر الهواء على الحركة. على الرغم من أن هذا الجهاز موجود منذ نصف قرن، إلا أنه لا يزال جزءًا أساسيًا في نقل الهواء من مكان إلى آخر. يتضمن هذا الجهاز محركًا لتشغيله، كما يحتوي على غطاء لضمان السلامة، بالإضافة إلى شفرات ذات أشكال خاصة. تكون الشفرات عادة منحنية ومائلة نحو الأمام، وهو الشكل الأمثل لدفع الهواء.

McMaster Electric's مروحة طرد مركزي يمكن استخدامها في عدة صناعات ومواقع. لديها مجموعة من الميزات الصغيرة التي تجعلها مفيدة للغاية. على سبيل المثال، يمكنها تحمل ضغوطاً كبيرة وتدفع كميات هائلة من الهواء. ويصبح هذا أمراً بالغ الأهمية في التطبيقات التي تتطلب كميات كبيرة من الهواء بشكل فوري. هذه المراوح الصغيرة أيضاً هادئة للغاية، مما يسمح للمكاتب والمستشفيات بأن تكون أكثر هدوءاً من حيث الصوت، حيث يحتاج الأشخاص إلى العمل أو الاسترخاء دون أن يواجهوا ضوضاء مزعجة. أما المجالات الأخرى التي تُستخدم فيها هذه المراوح فتشمل المناطق التي تتطلب هواءً نقياً مثل مصانع الأغذية حيث تُصنع وتُخزن الأطعمة، وشركات الأدوية التي تُنتج فيها الأدوية. فهي تُعد جزءاً مهماً في مختلف الصناعات التي يُعد فيها الهواء النظيف أمراً حاسماً.

أمر آخر شركة McMaster Electric مروحة نافثة طردية تُعرف بأنها فعالة من حيث الكفاءة في استخدام الطاقة. فهي تستهلك طاقة أقل من معظم المراوح الأخرى، ومع ذلك يمكنها إزالة نفس كمية الهواء. لا تؤدي أداءً جيدًا فحسب من حيث تحريك الهواء، ولكن هذه الكفاءة في استخدام الطاقة تساعد أيضًا في تقليل فواتير الكهرباء. وبعيدًا عن توفير الطاقة، فإن هذه المراوح تحتاج إلى صيانة دورية بسيطة للحفاظ على عملها. إذا كانت تعمل بشكل صحيح، فسوف توفر أيضًا تكاليف الإصلاح والاستبدال على طول الخط، لذا يُوصى بإجراء فحوصات دورية.

لشركة McMaster Electric مروحة طرد مركزي بمنحنى للأمام , يعد التركيب المناسب أمرًا بالغ الأهمية. في التركيب الصحيح، يعني ذلك وظيفة أفضل للمروحة وتسريع تدفق الهواء. أما المروحة المركبة بشكل غير صحيح فتعني عدم فعاليتها. والصيانة الدورية للمروحة أمر بالغ الأهمية أيضًا. فالصيانة الوقائية البسيطة، مثل الفحص المنتظم للمرشحات، يمكن أن تضمن بقاء تدفق الهواء غير مسدود ويعمل بشكل صحيح. تعمل المروحة بكفاءة أكبر إذا كانت المرشحات نظيفة وتسمح بتدفق الهواء بسلاسة.

شركة McMaster Electric مروحة طردية من نوع EC صُنعت هذه المنافيخ بتقنية جديدة، مما أدى إلى إطالة عمرها وتحسين أدائها. كما طُوّرت منافيخ عالية الكفاءة بفضل المواد الجديدة وتقنيات المحركات وأنظمة التحكم الذكية. تتيح هذه التطورات للمنافيخ الجديدة العمل بهدوء أكبر، مما يوفر أداةً أكثر إحكامًا وقوةً لنفخ الهواء الآن مقارنةً بالماضي. ونظرًا لتطور التقنية وكفاءتها المتزايدة، يمكننا أن نتوقع نفس النتائج من هذه المنافيخ مع مرور الوقت.

بخبرة تزيد عن 20 عامًا في مجالات الروبوتات والإنترنت من الأشياء (IoT) والصناعات automotive والرعاية الصحية، نحن نقدم دعمًا فنيًا مخصصًا وحلول هندسية تتناسب مع متطلبات الأعمال المحددة. تضمن خدماتنا المخصصة من البداية حتى النهاية دمجًا سلسًا وموثوقية على المدى الطويل.

تأسست في عام 2001، ونستفيد من خبرتنا متعددة الجنسيات لتوفير حلول كهربائية وأتمتة مخصصة للعملاء في أكثر من 150 دولة. تضمن خدماتنا الهندسية المخصصة أن تتلقى الشركات في جميع أنحاء العالم حلولاً عالية الأداء ومحددة للقطاع الصناعي، مما يعزز الكفاءة والموثوقية.

مكرسين لتطوير الكهربة والأتمتة، نقوم بدمج حلول تقنية مبنية حسب الطلب لتحسين الإنتاج وتقليل التكاليف والحد من الأثر البيئي. تساعد خبرتنا في أنظمة الطاقة عالية الكفاءة والأتمتة الذكية الشركات على تحقيق نمو مستدام من خلال حلول مخصصة.

من التصنيع automotive إلى الأتمتة الصناعية والإلكترونيات الاستهلاكية والتكنولوجيا الطبية، يتضمن نطاق منتجاتنا الواسع تصميمًا مخصصًا للروبوتات وحلول الإنترنت من الأشياء (IoT) وأنظمة الأتمتة الذكية. نحن نقدم خيارات تخصيص مرنة لتلبية الاحتياجات المتغيرة للصناعات العالمية.